- Product Detail

- Make an inquiry

Features

Equivalent to Burgmann LL9DJUE

API 682 Category 2 and 3, Type A,

Arrangement 2 seal

Dual seal in face-to-back arrangement

Dry contact outer seal (containment seal)

Balanced

Cartridge unit

Stationary multiple springs

Solid seal faces

Operating range

Pressure (primary seal): p = vacuum ... 60 bar (870 PSI)

Pressure (secondary seal): p = 2.75 bar (40 PSI) normal operation,max. 60 bar (870 PSI) in wet operation

Temperature: -40 °C … +176 °C (-40 °F … +349 °F)*

Sliding velocity: ... 25 m/s (82 ft/s)

Viscosity: 300 mPas

Solids content: ... 0.5 wt.%

* Engineered up to 260 °C (500 °F) with FFKM (K) secondary seals

Materials

Seal ring (primary seal): Blister resistant carbon,Silicon carbide SSiC (Q1), RBSiC (Q2)

Seal ring (secondary seal): Special carbon

Mating ring:Silicon carbide SSiC (Q1), RBSiC (Q2)

Secondary seals:FKM (V), FFKM (K), EPDM (E), NBR (P)

Springs: Hastelloy® C-276 (M5)

Metal parts: CrNiMo steel 316 (G)

Recommended applications

Refining technology)

Oil and gas industry

Petrochemical industry

Chemical industry

Power plant technology

Light volatile hydrocarbons

LPG plants

API 610 / ISO 13709 pumps

Process pumps

Advantages

Outer seal which can be used for flashing as well as non-flashing applications prevents hazardous emissions in case of inboard seal failure

Low heat generation and power consumption due to narrow seal face width of inner seal

Longer seal life

Good followability due to no influence from run-out, squareness or vibration of the shaft

Pressure-balanced design prevents mating ring being forced out under reverse pressure

No damage to shaft sleeve as dynamic

O-Ring is not in direct contact with the sleeve

Equivalent to Burgmann LL9DJUE

API 682 Category 2 and 3, Type A,

Arrangement 2 seal

Dual seal in face-to-back arrangement

Dry contact outer seal (containment seal)

Balanced

Cartridge unit

Stationary multiple springs

Solid seal faces

Operating range

Pressure (primary seal): p = vacuum ... 60 bar (870 PSI)

Pressure (secondary seal): p = 2.75 bar (40 PSI) normal operation,max. 60 bar (870 PSI) in wet operation

Temperature: -40 °C … +176 °C (-40 °F … +349 °F)*

Sliding velocity: ... 25 m/s (82 ft/s)

Viscosity: 300 mPas

Solids content: ... 0.5 wt.%

* Engineered up to 260 °C (500 °F) with FFKM (K) secondary seals

Materials

Seal ring (primary seal): Blister resistant carbon,Silicon carbide SSiC (Q1), RBSiC (Q2)

Seal ring (secondary seal): Special carbon

Mating ring:Silicon carbide SSiC (Q1), RBSiC (Q2)

Secondary seals:FKM (V), FFKM (K), EPDM (E), NBR (P)

Springs: Hastelloy® C-276 (M5)

Metal parts: CrNiMo steel 316 (G)

Recommended applications

Refining technology)

Oil and gas industry

Petrochemical industry

Chemical industry

Power plant technology

Light volatile hydrocarbons

LPG plants

API 610 / ISO 13709 pumps

Process pumps

Advantages

Outer seal which can be used for flashing as well as non-flashing applications prevents hazardous emissions in case of inboard seal failure

Low heat generation and power consumption due to narrow seal face width of inner seal

Longer seal life

Good followability due to no influence from run-out, squareness or vibration of the shaft

Pressure-balanced design prevents mating ring being forced out under reverse pressure

No damage to shaft sleeve as dynamic

O-Ring is not in direct contact with the sleeve

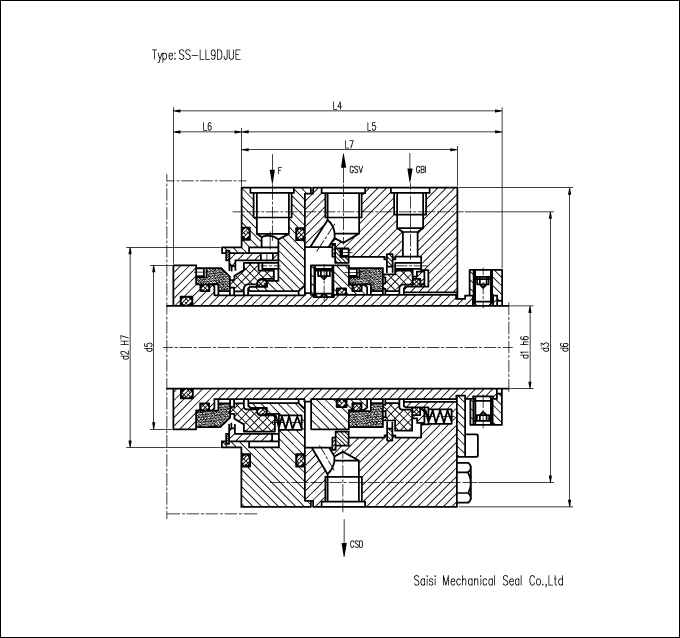

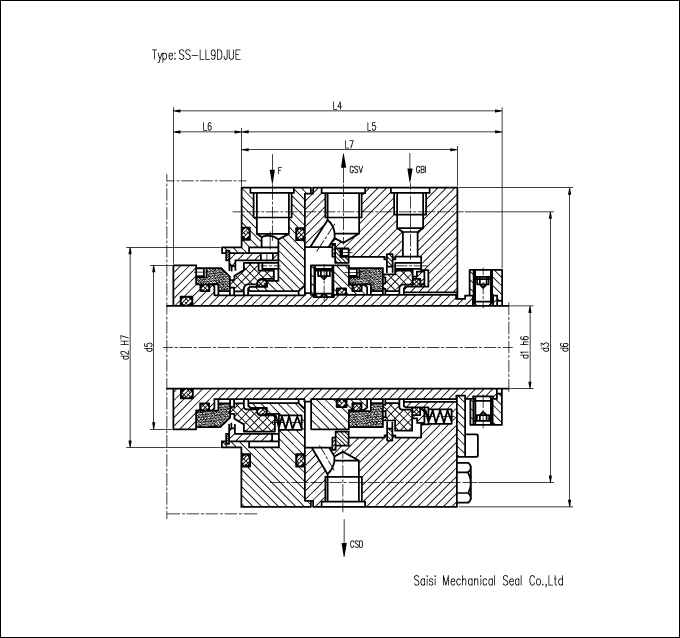

| SS-LL9DJUE Dimentions(mm) | ||||||||

| API/d1 | API/d2 | API/d3 | d5 | d6 | l4 | l5 | l6 | l7 |

| 20 | 70 | 105 | 51 | 128 | 128 | 98 | 30 | 80 |

| 30 | 80 | 115 | 63 | 138 | 130 | 98 | 32 | 80 |

| 40 | 90 | 125 | 74 | 148 | 133 | 98 | 35 | 80 |

| 50 | 100 | 140 | 84 | 168 | 142 | 107 | 35 | 87 |

| 60 | 120 | 160 | 99 | 188 | 142 | 107 | 35 | 87 |

| 70 | 130 | 170 | 108 | 198 | 142 | 107 | 35 | 87 |

| 80 | 140 | 180 | 120 | 208 | 142 | 107 | 35 | 87 |

| 90 | 160 | 205 | 138 | 238 | 150 | 115 | 35 | 93 |

| 100 | 170 | 215 | 148 | 248 | 150 | 115 | 35 | 93 |

| 110 | 180 | 225 | 157 | 258 | 155 | 115 | 40 | 93 |

Browse other products

-

SS-CR1: Grundfos pump seal

Click to view more>> -

SS-LB500: Burgmann LB500 replacement

Click to view more>> -

SS-M74-D: Burgmann M74-D replacement

Click to view more>> -

SS-1527: Eagle 1527(Sealol 1527)

Click to view more>> -

SS-560A: Replacement of 560A Elastomer bellows mechanical seal

Click to view more>>