- Product Detail

- Make an inquiry

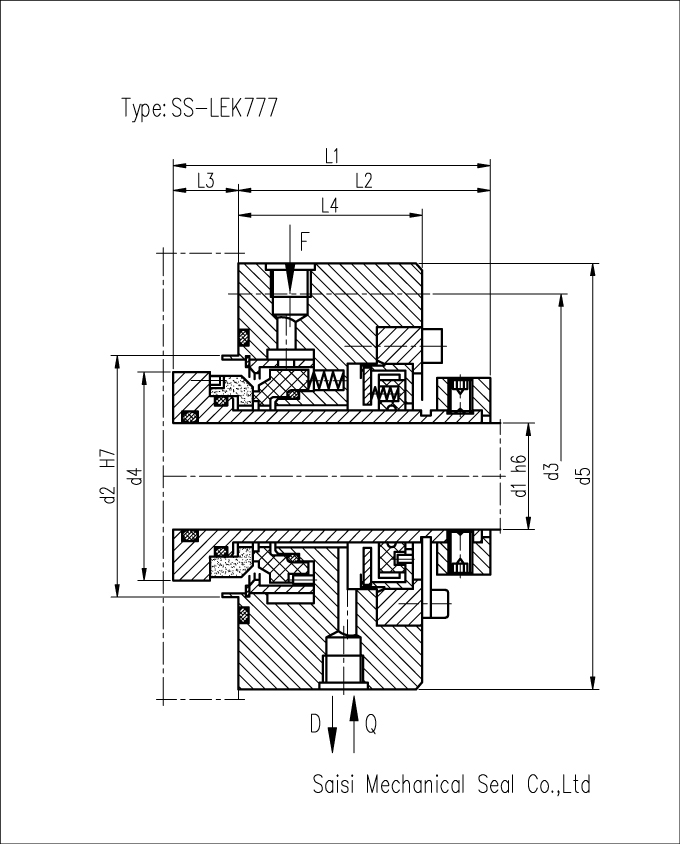

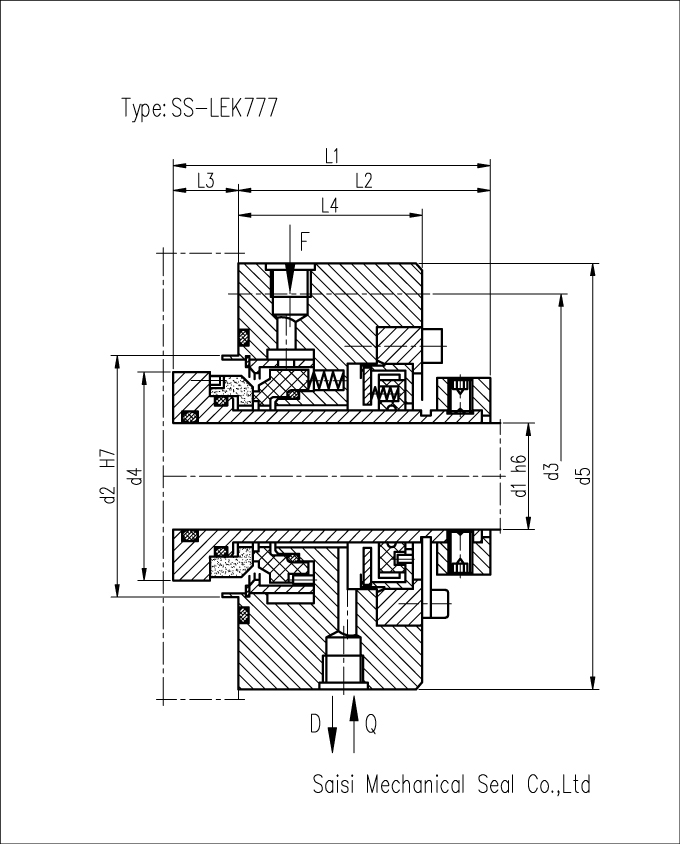

SS-LEK777: Burgmann LEK777 cartridge mechanical seal

Features

Equivalent to Burgmann LEK777

Single seal

Balanced

Cartridge unit

Stationary multiple springs

Solid seal faces

Operating range

Pressure (product seal): p = vacuum ... 60 bar ( … 870 PSI)

Temperature: -40 °C … +176 °C (-40 °F … +349 °F)*

Sliding velocity: vg = 50 m/s (164 ft/s)

Viscosity: ... 300 mPa·s

Solids content: ... 0.5 wt.%

* Engineered up to 260 °C (500 °F) with FFKM (K) secondary seals

Materials

Seal ring: Blister resistant carbon, Silicon carbide SSiC (Q1), RBSiC (Q2)

Mating ring: Silicon carbide SSiC (Q1), RBSiC (Q2)

Secondary seals: FKM (V), FFKM (K), EPDM (E), NBR (P)

Springs: Hastelloy® C-276 (M5)

Metal parts: CrNiMo steel 316 (G)

Recommended applications

Oil and gas industry

Power plant technology

Light volatile hydrocarbons

LPG plants

API 610 / ISO 13709 pumps

Process pumps

Recommended piping plans

Process side: 01, 02, 11, 12, 13, 14, 21, 22, 23, 31, 32, 41

Atmospheric side: 51, 61, 62, 65A, 65B, 66A, 66B

Advantages

Suitable for higher speeds

Good followability due to no influence from run-out, squareness or vibration of the shaft

Compact design

Low heat generation and power consumption due to narrow seal face width

Longer seal life

Pressure-balanced design prevents mating ring being forced out under reverse pressure

No damage to shaft sleeve as dynamic

O-Ring is not in direct contact with the sleeve

Features

Equivalent to Burgmann LEK777

Single seal

Balanced

Cartridge unit

Stationary multiple springs

Solid seal faces

Operating range

Pressure (product seal): p = vacuum ... 60 bar ( … 870 PSI)

Temperature: -40 °C … +176 °C (-40 °F … +349 °F)*

Sliding velocity: vg = 50 m/s (164 ft/s)

Viscosity: ... 300 mPa·s

Solids content: ... 0.5 wt.%

* Engineered up to 260 °C (500 °F) with FFKM (K) secondary seals

Materials

Seal ring: Blister resistant carbon, Silicon carbide SSiC (Q1), RBSiC (Q2)

Mating ring: Silicon carbide SSiC (Q1), RBSiC (Q2)

Secondary seals: FKM (V), FFKM (K), EPDM (E), NBR (P)

Springs: Hastelloy® C-276 (M5)

Metal parts: CrNiMo steel 316 (G)

Recommended applications

Oil and gas industry

Power plant technology

Light volatile hydrocarbons

LPG plants

API 610 / ISO 13709 pumps

Process pumps

Recommended piping plans

Process side: 01, 02, 11, 12, 13, 14, 21, 22, 23, 31, 32, 41

Atmospheric side: 51, 61, 62, 65A, 65B, 66A, 66B

Advantages

Suitable for higher speeds

Good followability due to no influence from run-out, squareness or vibration of the shaft

Compact design

Low heat generation and power consumption due to narrow seal face width

Longer seal life

Pressure-balanced design prevents mating ring being forced out under reverse pressure

No damage to shaft sleeve as dynamic

O-Ring is not in direct contact with the sleeve

| SS-LEK777 Dimentions(mm) | ||||||||

| API/d1 | API/d2 | API/d3 | d4 | d5 | l1 | l2 | l3 | l4 |

| 20 | 70 | 105 | 51 | 128 | 100 | 70 | 30 | 50 |

| 30 | 80 | 115 | 63 | 138 | 102 | 70 | 32 | 50 |

| 40 | 90 | 125 | 74 | 148 | 105 | 70 | 35 | 50 |

| 50 | 100 | 140 | 84 | 168 | 105 | 70 | 35 | 50 |

| 60 | 120 | 160 | 99 | 188 | 107 | 72 | 35 | 52 |

| 70 | 130 | 170 | 108 | 198 | 107 | 72 | 35 | 52 |

| 80 | 140 | 180 | 120 | 208 | 107 | 72 | 35 | 52 |

| 90 | 160 | 205 | 138 | 238 | 114 | 79 | 35 | 59 |

| 100 | 170 | 215 | 148 | 248 | 115 | 80 | 35 | 60 |

| 110 | 180 | 225 | 157 | 258 | 120 | 80 | 40 | 60 |

Browse other products

-

SS-BIA: Similar design with Burgmann EA560 John crane Type 21

Click to view more>> -

SS-ED560: Burgmann ED560 replacement

Click to view more>> -

SS-Cartex-DN: Burgmann Cartex Dual Seal replacement

Click to view more>> -

SS-HJ92N: Burgmann HJ92N replacement

Click to view more>> -

SS-58U: John crane Type 58U replacement

Click to view more>>