- Product Detail

- Make an inquiry

Features

Equivalent to Burgmann Cartex-GSDN

Stationary springs

Rotating seat

Double seal

Balanced

Cartridge unit

Standard version with V-grooves,

U-grooves optional (independent of direction of rotation)

Gas-lubricated, gas-buffered

Does not open in the event of buffer pressure failure, self closing at pressure reversal

Advantages

Contact-free operation

No friction on the seal faces, no heat generated at the seal or in the medium

No additional complex components to dissipate frictional heat

Maximum environmental protection and maximum efficiency

Operating range

Shaft diameter: d1 = 30 … 100 mm (1.18" ... 3.94")

Pressure:

p1 = 13 bar (189 PSI),

p3 = 16 bar (232 PSI)

with V-grooves (uni-directional)

p1 = 9 bar (131 PSI),

p3 = 12 bar (174 PSI)

with U-grooves (bi-directional)

Differential pressure (p3 - p1) = min. 3 bar (44 PSI)

Operating temperature limits for:

EPDM -20 °C … +140 °C (-4 °F ... +284 °F)

FFKM -20 °C … +120 °C (-4 °F ... 248 °F)

FKM -20 °C … +170 °C (-4 °F ... 338 °F)

Sliding velocity: vg = 4 … 15 m/s (13 ... 49 ft/s)

Axial movement: ± 1.0 mm

Materials

Seal face: Silicon carbide (Q1/Q19)

Seat: Silicon carbide (Q19/Q1)

Secondary seals: FKM (V), EPDM (E),FFKM (K)

Spring: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), Hastelloy®C-4 (M)

Equivalent to Burgmann Cartex-GSDN

Stationary springs

Rotating seat

Double seal

Balanced

Cartridge unit

Standard version with V-grooves,

U-grooves optional (independent of direction of rotation)

Gas-lubricated, gas-buffered

Does not open in the event of buffer pressure failure, self closing at pressure reversal

Advantages

Contact-free operation

No friction on the seal faces, no heat generated at the seal or in the medium

No additional complex components to dissipate frictional heat

Maximum environmental protection and maximum efficiency

Operating range

Shaft diameter: d1 = 30 … 100 mm (1.18" ... 3.94")

Pressure:

p1 = 13 bar (189 PSI),

p3 = 16 bar (232 PSI)

with V-grooves (uni-directional)

p1 = 9 bar (131 PSI),

p3 = 12 bar (174 PSI)

with U-grooves (bi-directional)

Differential pressure (p3 - p1) = min. 3 bar (44 PSI)

Operating temperature limits for:

EPDM -20 °C … +140 °C (-4 °F ... +284 °F)

FFKM -20 °C … +120 °C (-4 °F ... 248 °F)

FKM -20 °C … +170 °C (-4 °F ... 338 °F)

Sliding velocity: vg = 4 … 15 m/s (13 ... 49 ft/s)

Axial movement: ± 1.0 mm

Materials

Seal face: Silicon carbide (Q1/Q19)

Seat: Silicon carbide (Q19/Q1)

Secondary seals: FKM (V), EPDM (E),FFKM (K)

Spring: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), Hastelloy®C-4 (M)

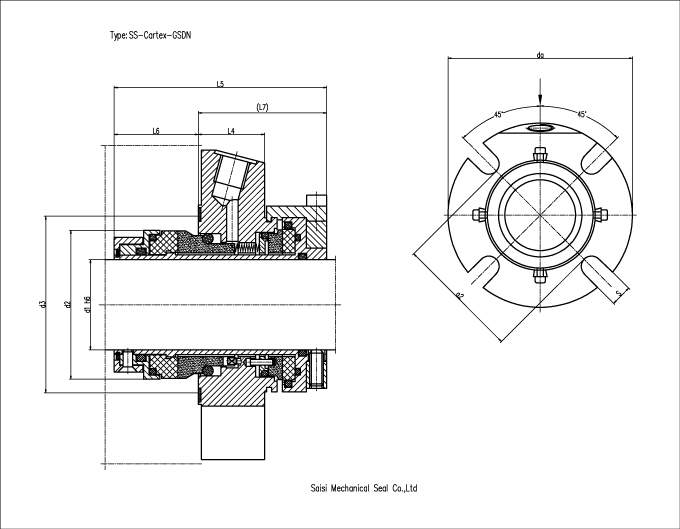

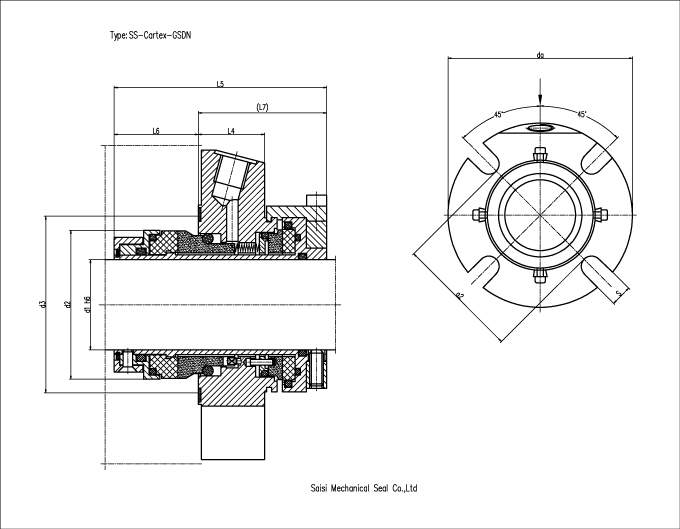

| SS-Cartex-GSDN Dimensions(mm) | ||||||||||

| d1 | d2 | d3(min) | d3(max) | l4 | l5 | l6 | l7 | a2 | da | s |

| 30 | 52 | 54 | 57 | 25.4 | 86 | 33 | 53 | 67 | 105 | 14 |

| 33 | 55 | 57 | 60 | 25.4 | 86 | 33 | 53 | 70 | 108 | 14 |

| 35 | 57.5 | 59 | 62 | 25.4 | 86 | 33 | 53 | 72 | 110 | 14 |

| 38 | 61 | 63 | 70 | 25.4 | 86 | 33 | 53 | 75 | 123 | 14 |

| 40 | 61 | 63 | 70 | 25.4 | 86 | 33 | 53 | 77 | 123 | 16 |

| 43 | 64 | 66 | 70 | 25.4 | 86 | 33 | 53 | 80 | 133 | 16 |

| 45 | 67 | 68 | 75 | 25.4 | 86 | 33 | 53 | 82 | 138 | 16 |

| 48 | 70 | 71 | 77 | 25.4 | 86 | 33 | 53 | 85 | 138 | 16 |

| 50 | 71 | 73 | 78 | 25.4 | 86 | 33 | 53 | 87 | 148 | 16 |

| 53 | 75.3 | 77 | 82 | 28.5 | 89 | 33 | 56 | 97 | 148 | 18 |

| 60 | 83.5 | 85 | 90 | 28.5 | 89 | 33 | 56 | 104 | 155 | 18 |

| 65 | 93 | 95 | 102 | 25.4 | 100 | 41.6 | 58.4 | 116 | 163 | 18 |

| 70 | 101 | 102 | 110 | 25.4 | 100 | 41.6 | 58.4 | 124 | 178 | 18 |

| 75 | 107 | 108 | 119 | 28 | 107 | 41.6 | 58.4 | 129 | 193 | 18 |

| 80 | 111 | 111 | 124 | 28 | 107 | 41.6 | 58.4 | 129 | 198 | 18 |

| 90 | 121 | 121 | 131 | 28 | 107 | 41.6 | 58.4 | 140 | 205 | 22 |

| 100 | 130 | 132 | 144 | 28 | 107 | 41.6 | 58.4 | 154 | 218 | 22 |

Browse other products

-

SS-MFL65: Burgmann MFL65 replacement

Click to view more>> -

SS-AD510/SS-AD520: Burgmann AD510/AD520 replacement

Click to view more>> -

SS-M74-D: Burgmann M74-D replacement

Click to view more>> -

SS-LB500: Burgmann LB500 replacement

Click to view more>> -

SS-Type 32: John crane Type 32 replacement

Click to view more>>