- Product Detail

- Make an inquiry

Features

Repalcement of Burgmann APItex

Single and dual seals

Cartridge

Seal design according API 682 / ISO 21049

Category 1, Type A, Arrangement 1, 2 or 3

Balanced

Independent of direction of rotation

Shrink-fitted seal faces

Solid seats

Single seal with API Plan 11 and 61 (Apitex-SA)

Dual seals with API Plan 52 / 53

Operating range

Shaft diameter: d1 = 20 … 110 mm (0.750" … 4.300"),other sizes on request

Pressure: p1 = 22 bar (319 PSI)

Temperature: t = -40 °C … 260 °C (-40 °F … 500 °F)(>220 °C (428 °F) please inquire)

Sliding velocity: vg = 23 m/s (75 ft/s)

Materials

Seal face: Carbon graphite antimony impregnated (A), Silicon carbide sintered pressureless (Q12)

Seat: Silicon carbide sintered pressureless (Q1)

Secondary seals: FKM (V), FFKM (K), NBR (P), EPDM (E)

Springs: Hastelloy® C-4 (M)* and C-276 (M5)

Metal parts: CrNiMo steel (G)

* EagleBurgmann standard

Advantages

Suitable for pressure reversal

Insensitive to shaft deflections and process fluctuations

Cover distortion cannot cause seat misalignment

Good heat dissipation

No external pump necessary

Pre-assembled unit, ready to install

Low space requirements

Security due to proofed design

Springs protected from the product

Repalcement of Burgmann APItex

Single and dual seals

Cartridge

Seal design according API 682 / ISO 21049

Category 1, Type A, Arrangement 1, 2 or 3

Balanced

Independent of direction of rotation

Shrink-fitted seal faces

Solid seats

Single seal with API Plan 11 and 61 (Apitex-SA)

Dual seals with API Plan 52 / 53

Operating range

Shaft diameter: d1 = 20 … 110 mm (0.750" … 4.300"),other sizes on request

Pressure: p1 = 22 bar (319 PSI)

Temperature: t = -40 °C … 260 °C (-40 °F … 500 °F)(>220 °C (428 °F) please inquire)

Sliding velocity: vg = 23 m/s (75 ft/s)

Materials

Seal face: Carbon graphite antimony impregnated (A), Silicon carbide sintered pressureless (Q12)

Seat: Silicon carbide sintered pressureless (Q1)

Secondary seals: FKM (V), FFKM (K), NBR (P), EPDM (E)

Springs: Hastelloy® C-4 (M)* and C-276 (M5)

Metal parts: CrNiMo steel (G)

* EagleBurgmann standard

Advantages

Suitable for pressure reversal

Insensitive to shaft deflections and process fluctuations

Cover distortion cannot cause seat misalignment

Good heat dissipation

No external pump necessary

Pre-assembled unit, ready to install

Low space requirements

Security due to proofed design

Springs protected from the product

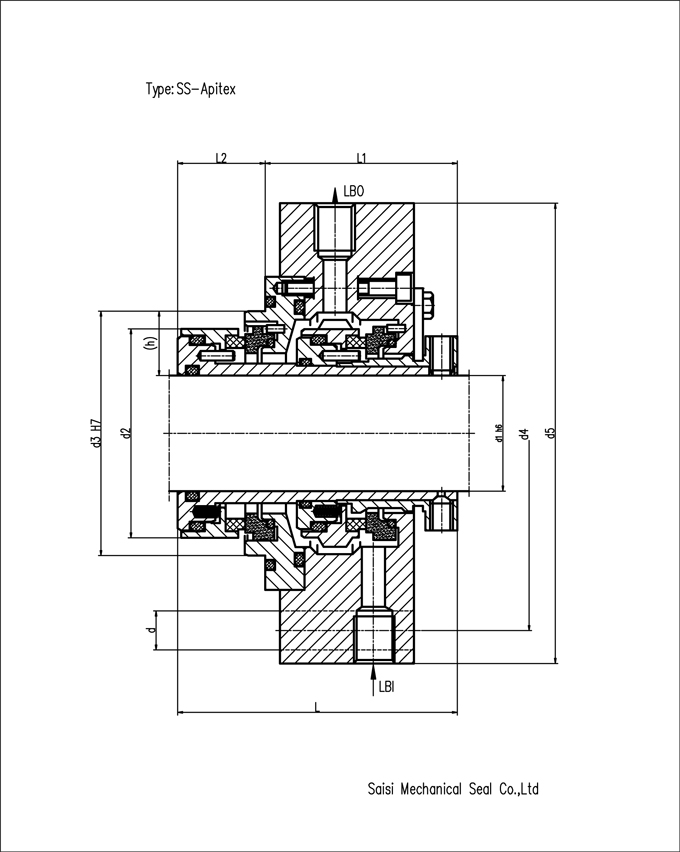

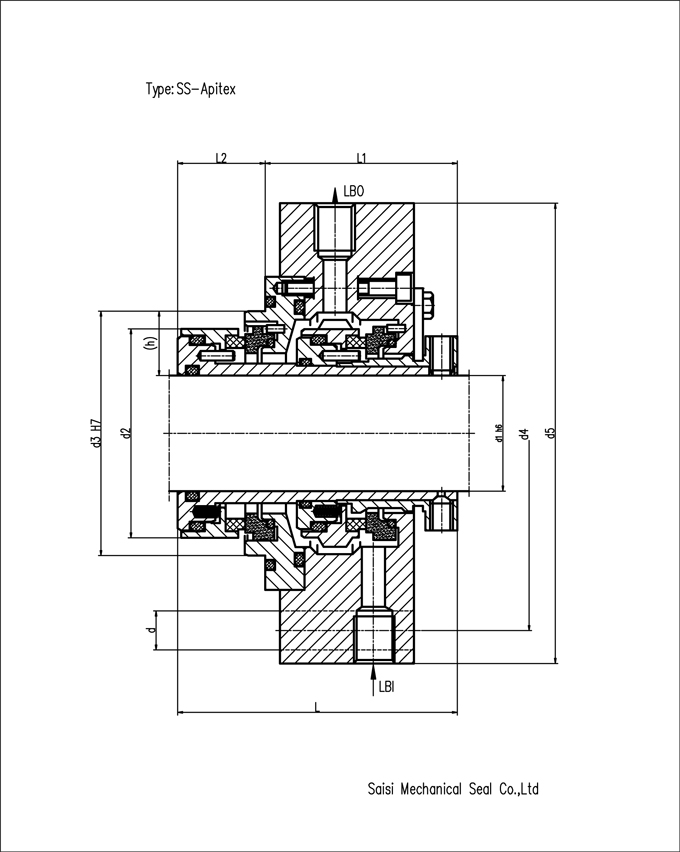

| SS-APItex Dimensions(mm) | ||||||||||

| d1 | d2 | d3 | d4 | d5 | l | l1 | l2 | d | Anz. | h (min.) |

| 20 | 50.4 | 58 | 105 | 127 | 96.5 | 68.5 | 28 | 13.5 | 4 | 19.05 |

| 25 | 55.4 | 63 | 110 | 132 | 96.5 | 68.5 | 28 | 13.5 | 4 | 19.05 |

| 30 | 60.4 | 68 | 115 | 137 | 96.5 | 68.5 | 28 | 13.5 | 4 | 19.05 |

| 35 | 65.4 | 73 | 120 | 142 | 96.5 | 68.5 | 28 | 13.5 | 4 | 19.05 |

| 40 | 70.4 | 78 | 125 | 147 | 96.5 | 68.5 | 28 | 13.5 | 4 | 19.05 |

| 45 | 75.4 | 83 | 135 | 162 | 96.5 | 68.5 | 28 | 17.5 | 4 | 19.05 |

| 50 | 80.4 | 88 | 140 | 167 | 100 | 72 | 28 | 17.5 | 4 | 19.05 |

| 55 | 85.4 | 93 | 145 | 172 | 100 | 72 | 28 | 17.5 | 4 | 19.05 |

| 60 | 96 | 105 | 160 | 187 | 127.5 | 88 | 39.5 | 17.5 | 4 | 22.22 |

| 65 | 101 | 110 | 165 | 192 | 127.5 | 88 | 39.5 | 17.5 | 4 | 22.22 |

| 70 | 106 | 115 | 170 | 197 | 127.5 | 88 | 39.5 | 17.5 | 4 | 22.22 |

| 75 | 111 | 120 | 175 | 202 | 127.5 | 88 | 39.5 | 17.5 | 4 | 22.22 |

| 80 | 116 | 125 | 185 | 213 | 127.5 | 88 | 39.5 | 22 | 4 | 22.22 |

| 85 | 123.5 | 136 | 190 | 223 | 131.5 | 92 | 39.5 | 22 | 4 | 25.4 |

| 90 | 128.5 | 141 | 195 | 228 | 131.5 | 92 | 39.5 | 22 | 4 | 25.4 |

| 95 | 133.5 | 146 | 200 | 233 | 131.5 | 92 | 39.5 | 22 | 4 | 25.4 |

| 100 | 138.5 | 151 | 205 | 238 | 131.5 | 92 | 39.5 | 22 | 4 | 25.4 |

| 105 | 143.5 | 156 | 210 | 243 | 131.5 | 92 | 39.5 | 22 | 4 | 25.4 |

| 110 | 152.5 | 161 | 215 | 248 | 131.5 | 92 | 39.5 | 22 | 4 | 25.4 |

Browse other products

-

SS-Cartex-SN: Burgmann Cartex Single seal replacement

Click to view more>> -

SS-HRN: Burgmann HRN replacement

Click to view more>> -

SS-EH700: Burgmann EH700 replacement

Click to view more>> -

SS-Type 609: John crane Type 609 replacement

Click to view more>> -

SS-CSE: Burgmann CSE replacement

Click to view more>>