- Product Detail

- Make an inquiry

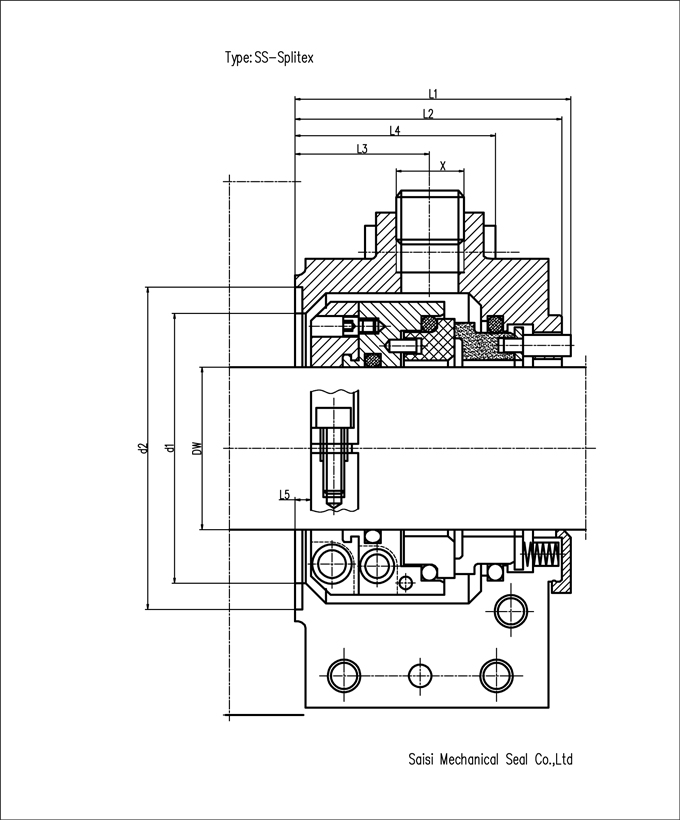

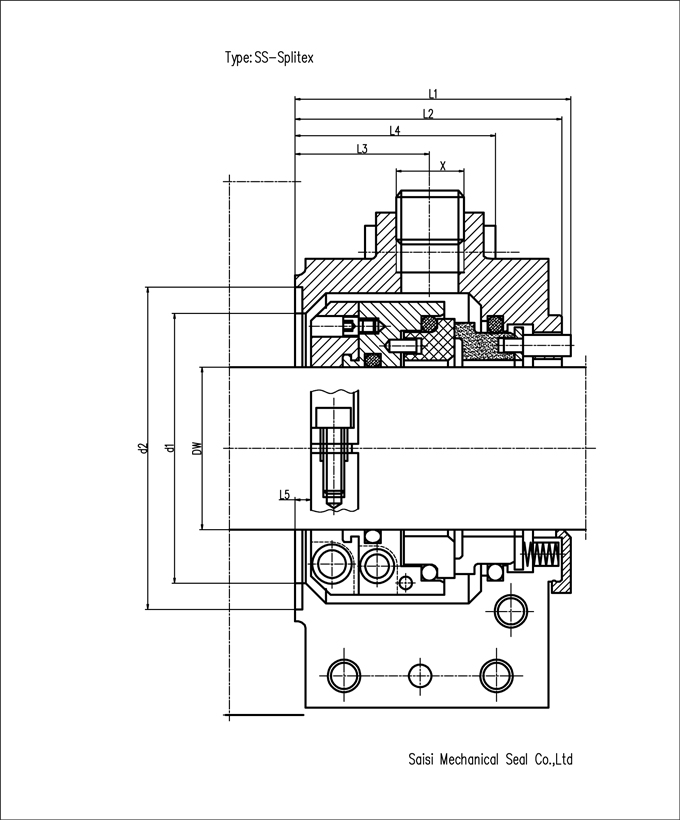

SS-Splitex: Burgmann Splitex split mechanical seal

Structure Description

Equivalent to Burgmann Splitex seal

Fully split single seal, 2 x 2 segments, preassembled

Semi-cartridge

Balanced

Stationary springs

Bi-directional

External pressurization

Built-in flushing connections

Operating range

Shaft diameter: d1 = 50 … 150 mm (1.940" … 6.000")

Pressure: p1 = 10 bar (145 PSI)

Temperature: t = -40 ... +150 °C (- 40 … + 300 °F), above 80 °C (175 °F) flush is recommended

Sliding velocity: vg = 10 m/s (33 ft/s)

Axial movement: ± 1.5 mm (1/16")

Radial movement: ± 0.8 mm (1/32")

Materials

Seal face: Carbon graphite antimoniny impregnated (A), Silicon carbide (Q6)

Seat: Silicon carbide (Q6)

Secondary seals: FKM (V), EPDM (E), NBR(P)

Springs: CrNiMo steel (G)

Metal parts: CrNiMo steel (G)

Advantages

*Reduced repair and downtime: 2 x 2 preassembled design speeds up and simplifies installation installation because pump does not have to be disassembled.

*Long service life: precise pre-alignment because of pre-assembled segments.Stationary springs which are protected from the product prevent clogging.

*Greater flexibility during installation: no modification necessary because the seal is located outside of the stuffing box.

*Shaft protection: uniform torque transmission via clamping ring prevents damage caused by set screws.

*Dependable operation: mechanical decoupling of clamping ring (torque transmission) avoids distortion of the seat.

*Simple monitoring of the seal during operation because of mechanical wear indicator on the seal face.

*Low leakage: elimination of secondary seals eliminates leakage paths between split components.

*High tolerance to shaft deflections ensured by stationary design and elastic seat mounting (gasket).

Structure Description

Equivalent to Burgmann Splitex seal

Fully split single seal, 2 x 2 segments, preassembled

Semi-cartridge

Balanced

Stationary springs

Bi-directional

External pressurization

Built-in flushing connections

Operating range

Shaft diameter: d1 = 50 … 150 mm (1.940" … 6.000")

Pressure: p1 = 10 bar (145 PSI)

Temperature: t = -40 ... +150 °C (- 40 … + 300 °F), above 80 °C (175 °F) flush is recommended

Sliding velocity: vg = 10 m/s (33 ft/s)

Axial movement: ± 1.5 mm (1/16")

Radial movement: ± 0.8 mm (1/32")

Materials

Seal face: Carbon graphite antimoniny impregnated (A), Silicon carbide (Q6)

Seat: Silicon carbide (Q6)

Secondary seals: FKM (V), EPDM (E), NBR(P)

Springs: CrNiMo steel (G)

Metal parts: CrNiMo steel (G)

Advantages

*Reduced repair and downtime: 2 x 2 preassembled design speeds up and simplifies installation installation because pump does not have to be disassembled.

*Long service life: precise pre-alignment because of pre-assembled segments.Stationary springs which are protected from the product prevent clogging.

*Greater flexibility during installation: no modification necessary because the seal is located outside of the stuffing box.

*Shaft protection: uniform torque transmission via clamping ring prevents damage caused by set screws.

*Dependable operation: mechanical decoupling of clamping ring (torque transmission) avoids distortion of the seat.

*Simple monitoring of the seal during operation because of mechanical wear indicator on the seal face.

*Low leakage: elimination of secondary seals eliminates leakage paths between split components.

*High tolerance to shaft deflections ensured by stationary design and elastic seat mounting (gasket).

| SS-Splitex Dimensions(Inches) | ||||||||||||

| dw | dw | d1 | d2 | da | A | S | l1 | l2 | l3 | l4 | l5 | X |

| 1.940 | 49.276 | 2.953 | 3.307 | 5.433 | 3.456 | 0.591 | 2.480 | 2.402 | 1.181 | 1.772 | 0.118 | 3/8 NPT |

| 2.000 | 50.800 | 2.953 | 3.307 | 5.433 | 3.456 | 0.591 | 2.480 | 2.402 | 1.181 | 1.772 | 0.118 | 3/8 NPT |

| 2.125 | 53.975 | 3.110 | 3.465 | 5.787 | 3.622 | 0.591 | 2.480 | 2.402 | 1.142 | 1.772 | 0.118 | 3/8 NPT |

| 2.375 | 60.325 | 3.504 | 3.976 | 5.866 | 4.134 | 0.689 | 2.520 | 2.441 | 1.181 | 1.811 | 0.118 | 3/8 NPT |

| 2.438 | 61.925 | 3.642 | 4.114 | 6.181 | 4.272 | 0.689 | 2.520 | 2.441 | 1.181 | 1.811 | 0.118 | 3/8 NPT |

| 2.500 | 63.500 | 3.642 | 4.114 | 6.181 | 4.272 | 0.689 | 2.520 | 2.441 | 1.181 | 1.811 | 0.118 | 3/8 NPT |

| 2.750 | 69.850 | 3.858 | 4.449 | 6.929 | 4.646 | 0.787 | 2.520 | 2.441 | 1.181 | 1.811 | 0.118 | 3/8 NPT |

| 2.938 | 74.625 | 4.213 | 4.803 | 7.559 | 5.000 | 0.787 | 2.559 | 2.480 | 1.299 | 1.850 | 0.118 | 3/8 NPT |

| 3.000 | 76.200 | 4.213 | 4.803 | 7.559 | 5.000 | 0.787 | 2.559 | 2.480 | 1.299 | 1.850 | 0.118 | 3/8 NPT |

| 3.250 | 82.550 | 4.331 | 5.197 | 7.520 | 5.315 | 0.787 | 2.559 | 2.480 | 1.220 | 1.850 | 0.118 | 3/8 NPT |

| 3.500 | 88.900 | 4.764 | 5.512 | 7.992 | 5.709 | 0.866 | 2.854 | 2.776 | 1.240 | 1.988 | 0.118 | 1/2 NPT |

| 3.625 | 92.075 | 4.764 | 5.512 | 7.992 | 5.709 | 0.866 | 2.854 | 2.776 | 1.240 | 1.988 | 0.118 | 1/2 NPT |

| 3.750 | 95.250 | 4.921 | 5.630 | 8.110 | 5.827 | 0.866 | 2.854 | 2.776 | 1.240 | 1.988 | 0.118 | 1/2 NPT |

| 3.875 | 98.425 | 5.157 | 5.906 | 8.504 | 6.102 | 0.866 | 2.854 | 2.776 | 1.240 | 1.988 | 0.118 | 1/2 NPT |

| 4.000 | 101.600 | 5.157 | 5.906 | 8.504 | 6.102 | 0.866 | 2.854 | 2.776 | 1.240 | 1.988 | 0.118 | 1/2 NPT |

| 4.250 | 107.950 | 5.591 | 6.496 | 9.055 | 6.693 | 0.866 | 2.854 | 2.776 | 1.240 | 1.988 | 0.118 | 1/2 NPT |

| 4.500 | 114.300 | 5.984 | 6.890 | 9.449 | 7.087 | 0.866 | 2.854 | 2.776 | 1.240 | 1.988 | 0.118 | 1/2 NPT |

| 4.750 | 120.650 | 5.984 | 6.890 | 9.449 | 7.087 | 0.866 | 2.854 | 2.776 | 1.240 | 1.988 | 0.118 | 1/2 NPT |

| 5.000 | 127.000 | 6.378 | 7.283 | 10.551 | 7.480 | 1.024 | 3.524 | 3.445 | 1.713 | 2.461 | 0.157 | 1/2 NPT |

| 5.500 | 139.700 | 6.890 | 7.874 | 11.929 | 8.071 | 1.024 | 3.524 | 3.445 | 1.713 | 2.461 | 0.157 | 1/2 NPT |

| 6.000 | 152.400 | 7.402 | 8.465 | 12.126 | 8.661 | 1.024 | 3.524 | 3.445 | 1.713 | 2.461 | 0.157 | 1/2 NPT |

| SS-Splitex Dimensions(mm) | ||||||||||||

| dw | dw | d1 | d2 | da | a | s | l1 | l2 | l3 | l4 | l5 | X |

| 50 | 1.969 | 75 | 84 | 138 | 88 | 15 | 63 | 61 | 30 | 45 | 3 | 3/8 NPT |

| 60 | 2.362 | 89 | 101 | 149 | 105 | 17.5 | 64 | 62 | 30 | 46 | 3 | 3/8 NPT |

| 70 | 2.756 | 98 | 113 | 176 | 118 | 20 | 64 | 62 | 30 | 46 | 3 | 3/8 NPT |

| 80 | 3.150 | 110 | 132 | 191 | 135 | 20 | 65 | 63 | 31 | 47 | 3 | 3/8 NPT |

| 90 | 3.543 | 121 | 140 | 203 | 145 | 22 | 72.5 | 70.5 | 31.5 | 50.5 | 3 | 1/2 NPT |

| 100 | 3.937 | 131 | 150 | 216 | 155 | 22 | 72.5 | 70.5 | 31.5 | 50.5 | 3 | 1/2 NPT |

| 110 | 4.331 | 142 | 165 | 230 | 170 | 22 | 72.5 | 70.5 | 31.5 | 50.5 | 3 | 1/2 NPT |

| 120 | 4.724 | 152 | 175 | 240 | 180 | 22 | 72.5 | 70.5 | 31.5 | 50.5 | 3 | 1/2 NPT |

| 125 | 4.921 | 162 | 185 | 268 | 190 | 26 | 89.5 | 87.5 | 43.5 | 62.5 | 4 | 1/2 NPT |

| 140 | 5.512 | 175 | 200 | 303 | 205 | 26 | 89.5 | 87.5 | 43.5 | 62 | 4 | 1/2 NPT |

| 150 | 5.906 | 188 | 215 | 308 | 220 | 26 | 89.5 | 87.5 | 43.5 | 62.5 | 4 | 1/2 NPT |