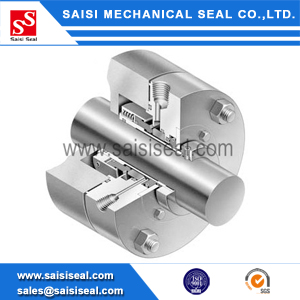

- Product Detail

- Make an inquiry

Structure description

Replacement of Burgmann LY9DSTT

API 682 Category 2 and 3, Type C,

Arrangement 3 seal

Dual seal in face-to-face arrangement

Balanced

Cartridge unit

Rotating metal bellows

Shrink fitted seal ring and solid mating ring

Operating range

Pressure single ply bellows: p = vacuum ... 20 bar (... 290 PSI)

Pressure double ply bellows: p = vacuum ... 35 bar (... 508 PSI)

Temperature: t = -200 °C ... +400 °C(-328 °F ... +752 °F)

Sliding velocity: vg ... 50 m/s (... 164 ft/s)

Viscosity: ... 1,000 mPas

Solids content: ... 0.5 wt.%

Materials

Seal ring: Blister resistant carbon,Silicon carbide SSiC (Q1), RBSiC (Q2)

Mating ring:Silicon carbide SSiC (Q1), RBSiC (Q2)

Bellows: Inconel® 718 (M6)

Secondary seals: Graphite (G)

Metal parts: CrNiMo steel 316 (G), Carpenter® 42 (T4)

Recommended applications

Refining technology

Oil and gas industry

Petrochemical industry

Chemical industry

Power plant technology

LPG plants

API 610 / ISO 13709 pumps

Process pumps

Advantages

Very compact design

Suitable for higher speeds

Good followability due to no influence from run-out, squareness or vibration of the shaft

Low heat generation and power consumption due to narrow seal face width

Longer seal life

Also available in double ply design

Suited for applications with extreme high and low temperatures

Absence of dynamic O-Ring eleminates/ reduces seal face hang-up

Bellows design minimizes variation in face load due to shaft expansion or face wear

Resistant to abrasive particles in the medium, no shaft or sleeve fretting

Replacement of Burgmann LY9DSTT

API 682 Category 2 and 3, Type C,

Arrangement 3 seal

Dual seal in face-to-face arrangement

Balanced

Cartridge unit

Rotating metal bellows

Shrink fitted seal ring and solid mating ring

Operating range

Pressure single ply bellows: p = vacuum ... 20 bar (... 290 PSI)

Pressure double ply bellows: p = vacuum ... 35 bar (... 508 PSI)

Temperature: t = -200 °C ... +400 °C(-328 °F ... +752 °F)

Sliding velocity: vg ... 50 m/s (... 164 ft/s)

Viscosity: ... 1,000 mPas

Solids content: ... 0.5 wt.%

Materials

Seal ring: Blister resistant carbon,Silicon carbide SSiC (Q1), RBSiC (Q2)

Mating ring:Silicon carbide SSiC (Q1), RBSiC (Q2)

Bellows: Inconel® 718 (M6)

Secondary seals: Graphite (G)

Metal parts: CrNiMo steel 316 (G), Carpenter® 42 (T4)

Recommended applications

Refining technology

Oil and gas industry

Petrochemical industry

Chemical industry

Power plant technology

LPG plants

API 610 / ISO 13709 pumps

Process pumps

Advantages

Very compact design

Suitable for higher speeds

Good followability due to no influence from run-out, squareness or vibration of the shaft

Low heat generation and power consumption due to narrow seal face width

Longer seal life

Also available in double ply design

Suited for applications with extreme high and low temperatures

Absence of dynamic O-Ring eleminates/ reduces seal face hang-up

Bellows design minimizes variation in face load due to shaft expansion or face wear

Resistant to abrasive particles in the medium, no shaft or sleeve fretting

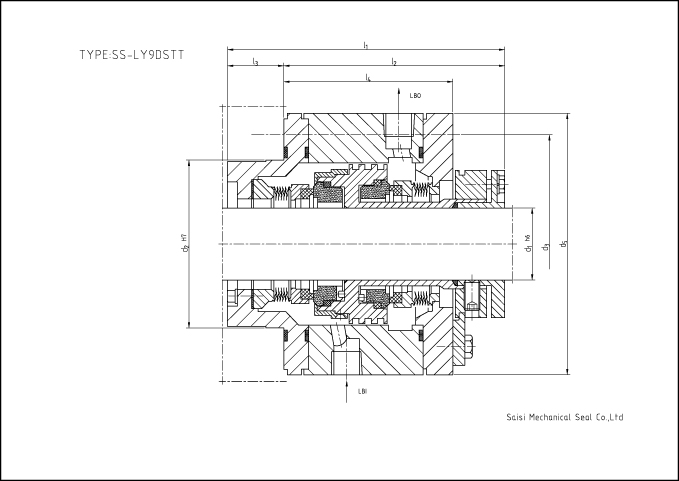

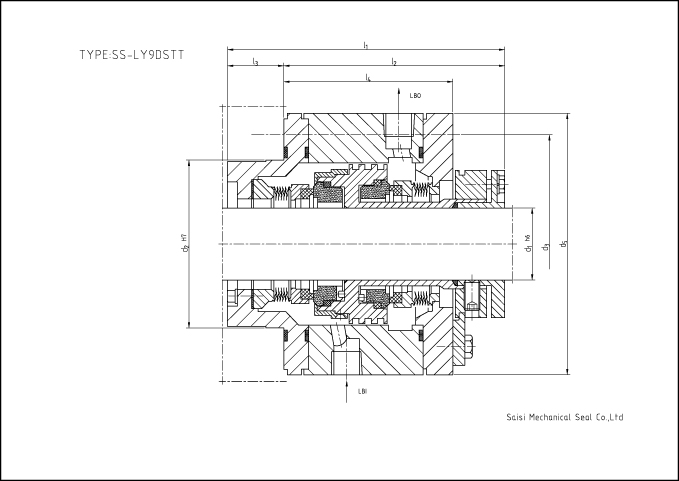

| SS-LY9DSTT Dimentions(mm) | |||||||

| API/d1 | API/d2 | API/d3 | d5 | l1 | l2 | l3 | l4 |

| 20 | 70 | 105 | - | - | - | - | - |

| 30 | 80 | 115 | 138 | 145 | 98 | 47 | 73 |

| 40 | 90 | 125 | 148 | 151 | 97 | 54 | 73.5 |

| 50 | 100 | 140 | 168 | 149 | 107 | 42 | 84 |

| 60 | 120 | 160 | 188 | 162 | 107 | 55 | 80 |

| 70 | 130 | 170 | 198 | 169 | 107 | 62 | 81,5 |

| 80 | 140 | 180 | 208 | 162 | 107 | 55 | 79 |

| 90 | 160 | 205 | 238 | 180 | 117 | 63 | 88.5 |

| 100 | 170 | 215 | 248 | 184 | 117 | 67 | 85 |

| 110 | 180 | 225 | 258 | 189 | 117 | 72 | 83.5 |

Browse other products

-

SS-Type 48: John crane Type 48LP/48MP/48HP

Click to view more>> -

SS-CR2: Grundfos pump seal

Click to view more>> -

SS-T0WP: AES T0WP/Flowserve AWP/Sterling SWP mechanical seal replacment

Click to view more>> -

SS-LY9DZSS: Burgmann LY9DZSS replacement

Click to view more>> -

SS-Convertor II: AES Convertor II cartridge seal

Click to view more>>